The Munich Institute of Robotics and Machine Intelligence (MIRMI) at the Technical University of Munich (TUM) has developed an automatic process for making soft sensors. These sensors function as universal measurement cells and can be attached to almost any kind of object. In use, they are able to provide a realistic emulation of the sensorimotor skills of a person.

“Detecting and sensing our environment is essential for understanding how to interact with it effectively,” says Sonja Gross, lead author. “This determines how we can perform certain tasks.”

Currently, the traditional force and torque sensors used in robotics are limited in terms of customization, and cannot be attached to arbitrary objects. To address these issues, the MIRMI team developed a soft, skin-like material that wraps around objects. They also designed a framework that largely automates the production process for this skin.

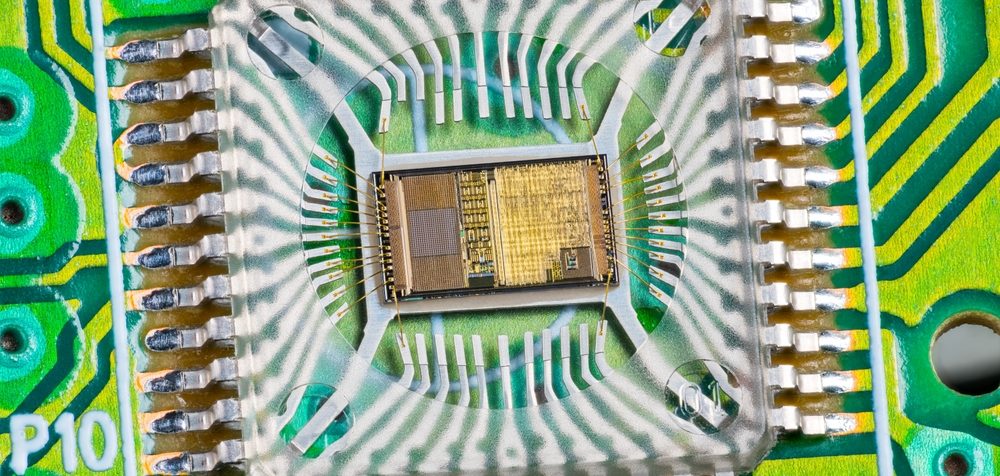

“We use software to build the structure for the sensory systems,” said co-author Diego Hidalgo-Carvajal. “We then send this information to a 3D printer where our soft sensors are made.”

The 3D printer injects a conductive black paste into liquid silicone. The silicone hardens, but the paste is enclosed by it and remains in liquid form. When the sensors are squeezed or stretched, their electrical resistance changes, relaying information to the system.

“That tells us how much compression or stretching force is applied to a surface. We use this principle to gain a general understanding of interactions with objects and, specifically, to learn how to control an artificial hand interacting with these objects,” stated Hidalgo.

The sensors embedded in silicon adjust to the surface in question, yet can still provide precise data that can be used for the interaction with the environment.

“The integration of these soft, skin-like sensors in 3D objects opens up new paths for advanced haptic sensing in artificial intelligence,” said MIRMI Executive Director Prof. Sami Haddadin. The sensors provide valuable data on compressive forces and deformations in real time—thus providing immediate feedback. This expands the range of perception of an object or a robotic hand—facilitating a more sophisticated and sensitive interaction. This work has the potential to bring about a general revolution in industries such as robotics, prosthetics and the human/machine interaction by making it possible to create wireless and customizable sensor technology for arbitrary objects and machines.”