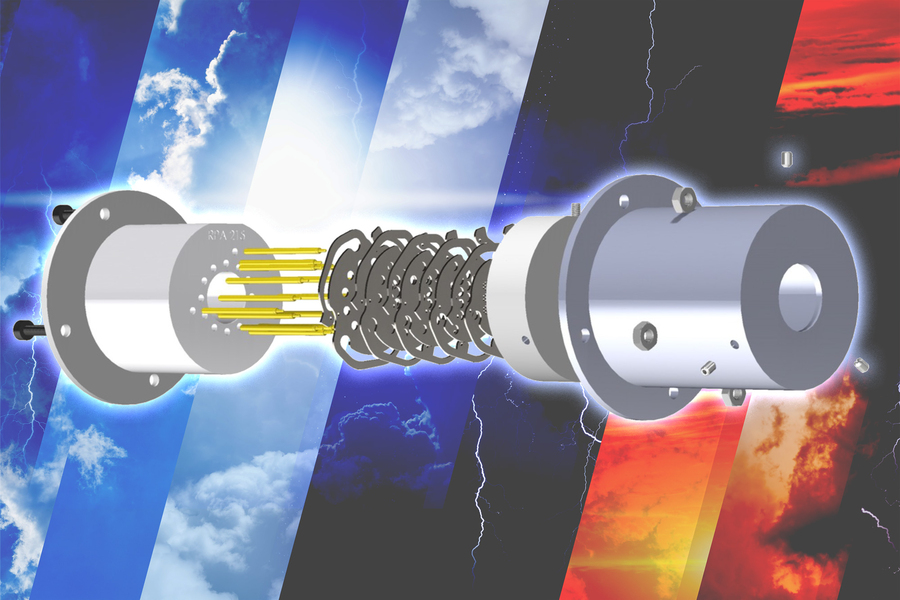

Researchers at MIT have created the first completely digitally manufactured plasma sensors for orbiting spacecraft. Plasma sensors, also called retarding potential analyzers (RPAs), are used to determine the chemical composition and ion energy distribution of the atmosphere.

At this time, semiconductor plasma sensors are manufactured in cleanrooms, an expensive and intricate fabrication process. MIT’s 3D-printed and laser-cut sensors can be produced very inexpensively and in only a few days, making them ideal for use on CubeSats.

“When you make this sensor in the cleanroom, you don’t have the same degree of freedom to define materials and structures and how they interact together. What made this possible is the latest developments in additive manufacturing,” Luis Fernando Velásquez-García, a principal scientist in the Microsystems Technology Laboratories (MTL) at MIT and senior author of the paper said.

The RPAs were created using a glass-ceramic material, which is not only more durable than traditional sensor materials but also allowed them to create sensors with complex shapes capable of withstanding the wide temperature swings encountered by satellites. The researchers used vat polymerization where a 3D structure is built one layer at a time by submerging it repeatedly into a vat of liquid material, and curing the material with ultraviolet light each time. Each layer is only 100 microns thick, which creates smooth, pore-free, complex ceramic shapes.

“Additive manufacturing can make a big difference in the future of space hardware. Some people think that when you 3D-print something, you have to concede less performance. But we’ve shown that is not always the case. Sometimes there is nothing to trade off,” said Velásquez-García.