Researchers in the Oregon State University College of Science have discovered a potential method of scrubbing carbon dioxide from industrial emissions using metal organic frameworks (MOFs). These inexpensive nanomaterials could become an important factor in improving carbon capture.

“The capture of carbon dioxide is critical for meeting net-zero emission targets,” said Kyriakos Stylianou, team leader and assistant professor of chemistry. “MOFs have shown a lot of promise for carbon capture because of their porosity and their structural versatility, but synthesizing them often means using reagents that are costly both economically and environmentally, such as heavy metal salts and toxic solvents.”

MOFs are able to intercept carbon dioxide molecules through adsorption as flue gasses pass through smokestacks. The water portion of smokestack gasses has prevented problems, however, as MOFs may lose their effectiveness in humid conditions, and drying the gasses is cost-prohibitive.

“So we sought to come up with a MOF to address the various limitations of the materials currently used in carbon capture: high cost, poor selectivity for carbon dioxide, low stability in humid conditions, and low CO2 uptake capacities,” Stylianou said.

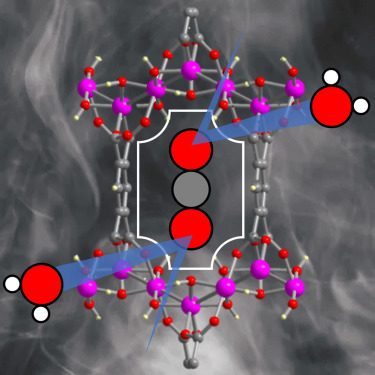

MOFs are crystalline, porous materials composed of positively charged metal ions surrounded by organic “linker” molecules known as ligands. They can be designed with a variety of components, which determine their properties.

“In this study we introduce a MOF composed of aluminum and a readily available ligand, benzene-1,2,4,5-tetracarboxylic acid,” Stylianou said. “The synthesis of the MOF happens in water and only takes a couple of hours. And the MOF has pores with a size comparable to that of CO2 molecules, meaning there’s a confined space for incarcerating the carbon dioxide.”

The resulting MOF worked well in damp conditions and also showed an affinity for carbon dioxide over nitrogen, an important factor as nitrogen oxides are an ingredient in flue gasses. Without that selectivity, the MOF would potentially be binding to the wrong molecules.

“This MOF is an outstanding candidate for wet post-combustion carbon capture applications,” Stylianou said. “It’s cost effective with exceptional separation performance and can be regenerated and reused at least three times with comparable uptake capacities.”