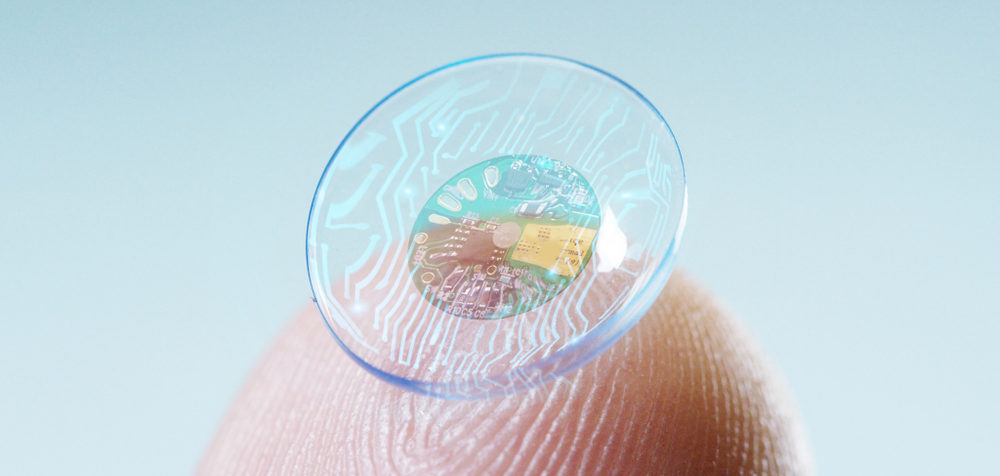

The Smart 3D Printing Research Team at the Korea Electrotechnology Research Institute (KERI) along with a team at Ulsan National Institute of Science and Technology (UNIST) have developed a core 3D printing process technology for smart contact lenses that can implement augmented reality (AR)-based navigation. Smart contact lenses attach to the human eye like a normal lens and are capable of providing various information.

Smart contact lenses with AR capabilities use electrochromic displays – where the color of a substance changes reversibly due to an electrochemical reaction – that can be driven with low power, and “Pure Prussian Blue” color, which enables quick contrast and transition between colors. The problem with this technique is that the color was coated on the substrate in the form of a film using the electric plating method, which limited the production of advanced displays that can express various information, such as letters, numbers, and images.

The KERI-UNIST team’s technique prints micro-patterns on a lens display using a 3D printer without applying voltage. The technology takes advantage of the meniscus phenomenon where a curved surface is formed on the outer wall of an ink droplet. Prussian blue is crystallized through solvent evaporation in the meniscus formed between the micronozzle and the substrate, enabling uniformly printed patterns on a substrate. Unlike conventional electroplating – where the substrate has to function as a conductor when voltage is applied – using the meniscus phenomenon means there is no restriction on the substrate that can be used because crystallization occurs by natural evaporation of the solvent.

The micro-patterns formed can be applied to both flat and curved surfaces. The research team’s micro-pattern technology is very fine (7.2 micrometers), and can be applied with continuous and uniform color.

It is expected that the new smart lenses’ primary purpose will be for navigation. The new technique would also be of use for any micro-patterning that uses Prussian blue

Dr. Seol Seung-Kwon’s of KERI said, “Our achievement is a development of 3D printing technology that can print functional micro-patterns on non-planar substrate that can commercialize advanced smart contact lenses to implement AR. It will greatly contribute to the miniaturization and versatility of AR devices.”